Do you love knowing what goes on behind the scenes? I do. Factory tours and 'How It's Made' type shows bring out the geek in me, especially when they relate to food. Naturally, I was eager to take the tour of Pearl Valley Cheese Company during my recent Ohio Dairy Adventure. I wanted to see how a 'big' cheese maker compared to the much smaller Laurel Valley, Kokoborrego, and Great Hill creameries I visited in the past.

Chuck Ellis, a fourth generation cheese maker, shared about his creamery. In 1928, Swiss immigrant Ernest Stalder blew a whistle daily to let local cow farmers know that he was beginning to make cheese and needed their milk. He produced one 200 pound wheel of Swiss cheese each day and returned the whey to the farmers to feed animals.

Pearl Valley Cheese Company grew over the years and now makes 25,000 pounds of cheese in eleven varieties daily. The company buys milk from eighty farms. Ten pounds of milk is required to make one pound of cheese which means Pearl Valley processes about a million pounds of milk every four days!

Milk arrives by truck and is tested for pathogens and antibiotics before filling large silos. A glycol cooling solution circulates the tank so the milk stays cool. From the silos, milk travels to a pasteurizer which heats the products to 168 degrees F for 16 seconds before being rapidly cooled and separated. The seperator allows cheese makers to regulate the fat in the cheese.

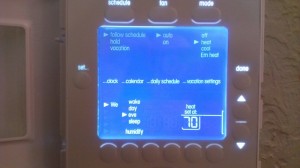

Next, milk for each batch of cheese is pumped into a computer-controlled vat. Temperature, time, stirring speeds and amount of rennet and culture are all monitored and recorded by the computer. Colby-type cheese spend approximately 2 hours and 20 minutes in the cooking vat; Swiss-type cheeses take three hours.

Whey is seperated from the curds in cloth-lined tubs. They are pressed and allowed to sit overnight. Then, the blocks are placed in a salt brine and stay there to absorb the salt for a few hours to overnight, depending on the type of cheese.

The blocks are packaged and cooled for one week. Finally, they head to the room temperature aging room for approximately a month. There, the holes in the Swiss cheese develop as bacterial cultures transform the flavor of the cheese and off-gas bubbles of carbon dioxide which form the 'eyes' of the cheese. Swiss cheese is graded by the size of the eyes, with Grade A having eyes of one quarter to three quarters of an inch. When the cheese is deemed finished, it is packaged and stored at refrigerator temperatures.

Chuck remarked that "Swiss is tough to make." There are only 42 creameries making Swiss in the country; nine are in Ohio.

Sustainable Cheese-making

Pearl Valley Cheese Company operates with an eye (Swiss cheese joke!) towards reducing their environmental impact. In the process of treating their waste water, they generate biogas that is used to heat boilers in the factory. They reduce waste (and generate income) by selling all by-products including whey which is made into whey protein concentrate and lactose for energy production. Solid by-products are used as fertilizer on cow-feed fields.

At the same time, Pearl Valley uses electronic tracking to label and monitor all batches of all cheeses so they can be traced back to each milk load. If there were ever a quality or health issue, they could pinpoint the error.

Tasting Pearl Valley Cheese

Look for Pearl Valley's new red, white, and blue label featuring Swiss mountains to buy their cheese from a local grocer. It is not particularly easy to find in Central Ohio, as 50% of the Pearl Valley cheese is privately labeled. Fortunately, you can purchase online or visit their factory in Fresno, Ohio, an hour and a half from Columbus. I recommend the Aged Swiss for those who like bold flavors and the Colby for those who are more inclined toward mild cheeses.

Pearl Valley Cheese Company

54775 Township Road 90

Fresno, OH 43824

(740) 545-6002

Disclosure: The American Dairy Association Mideast provided lodging, meals, and tour arrangements for the Ohio Dairy Tour.